Page 117 - 6634

P. 117

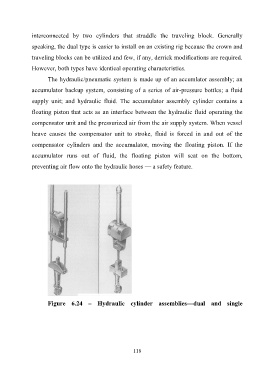

interconnected by two cylinders that straddle the traveling block. Generally

speaking, the dual type is easier to install on an existing rig because the crown and

traveling blocks can be utilized and few, if any, derrick modifications are required.

However, both types have identical operating characteristics.

The hydraulic/pneumatic system is made up of an accumlator assembly; an

accumulator backup system, consisting of a series of air-pressure bottles; a fluid

supply unit; and hydraulic fluid. The accumulator assembly cylinder contains a

floating piston that acts as an interface between the hydraulic fluid operating the

compensator unit and the pressurized air from the air supply system. When vessel

heave causes the compensator unit to stroke, fluid is forced in and out of the

compensator cylinders and the accumulator, moving the floating piston. If the

accumulator runs out of fluid, the floating piston will seat on the bottom,

preventing air flow onto the hydraulic hoses — a safety feature.

Figure 6.24 – Hydraulic cylinder assemblies—dual and single

118