Page 55 - Microsoft Word - 4236

P. 55

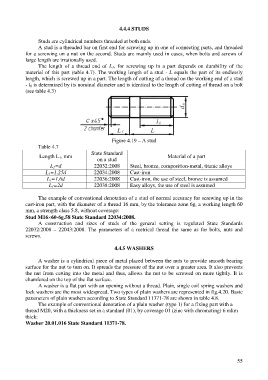

4.4.4 STUDS

Studs are cylindrical numbers threaded at both ends.

A stud is a threaded bar on first end for screwing up in one of connecting parts, and threaded

for a screwing on a nut on the second. Studs are mainly used in cases, when bolts and screws of

large length are irrationally used.

The length of a thread end of L 1, for screwing up in a part depends on durability of the

material of this part (table 4.7). The working length of a stud - L equals the part of its endlessly

length, which is screwed up in a part. The length of cutting of a thread on the working end of a stud

- l 0 is determined by its nominal diameter and is identical to the length of cutting of thread on a bolt

(see table 4.3)

Figure 4.19 – A stud

Table 4.7

State Standard

Length L 1, mm Material of a part

on a stud

L 1=d 22032:2008 Steel, bronze, composition-metal, titanic alloys

L 1=1,25d 22034:2008 Cast-iron

L 1=1,6d 22036:2008 Cast-iron, the use of steel, bronze is assumed

L 1=2d 22038:2008 Easy alloys, the use of steel is assumed

The example of conventional denotation of a stud of normal accuracy for screwing up in the

cast-iron part, with the diameter of a thread 16 mm, by the tolerance zone 6g, a working length 60

mm, a strength class 5.8, without coverage:

Stud M1660-6g.58 State Standard 22034:2008.

A construction and sizes of studs of the general setting is regulated State Standards

22032:2008 – 22043:2008. The parameters of a metrical thread the same as for bolts, nuts and

screws.

4.4.5 WASHERS

A washer is a cylindrical piece of metal placed between the nuts to provide smooth bearing

surface for the nut to turn on. It spreads the pressure of the nut over a greater area. It also prevents

the nut from cutting into the metal and thus, allows the nut to be screwed on more tightly. It is

chamfered on the top of the flat surface.

A washer is a flat part with an opening without a thread. Plain, single coil spring washers and

lock washers are the most widespread. Two types of plain washers are represented in fig.4.20. Basic

parameters of plain washers according to State Standard 11371-78 are shown in table 4.8.

The example of conventional denotation of a plain washer (type 1) for a fixing part with a

thread M20, with a thickness set in a standard (01), by coverage 01 (zinc with chromating) 6 mkm

thick:

Washer 20.01.016 State Standard 11371-78.

55