Page 61 - 6653

P. 61

Stability of the properties of the springs is due to a

decrease in the loss of elastic properties over time. Stabilization

of qualities is carried out by mechanical aging and defamation.

Aging occurs during periodic loading and unloading of the

spring for several hours at a frequency of 30 ... 50 Hz. The

disappointment consists of loading the spring with a load that

exceeds the estimated value, within 6 ... 48 hours.

The main requirement put to the springs is to ensure the

accuracy of the elastic characteristic, that is, the relationship

between axial force and deformation.

The defects of the springs arising during the operation

are cracks, breakages, wear of the surface of the supporting

turns, deformation and violation of the concentricity of the

turns, loss of stiffness. To detect these defects, examine the

springs with a four-magnifying magnifier and check the

elasticity of special devices. The spring is considered suitable

for further operation, if it is necessary to apply an effort

exceeding the minimum allowable to a certain size for its

compression (for the contraction springs of brake pads -

stretching). Оглядають пружини, які підлягають

дефектації, за необхідності використовують лупу. Під час

огляду особливу увагу звертають на наявність тріщин,

обломів і різницю еталонної пружини і пружини, яка

підлягає дефектації. Одержані результати записують у звіт.

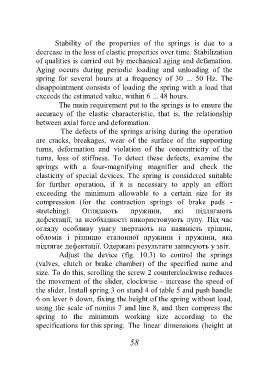

Adjust the device (fig. 10.3) to control the springs

(valves, clutch or brake chamber) of the specified name and

size. To do this, scrolling the screw 2 counterclockwise reduces

the movement of the slider, clockwise - increase the speed of

the slider. Install spring 3 on stand 4 of table 5 and push handle

6 on lever 6 down, fixing the height of the spring without load,

using the scale of nonius 7 and line 8, and then compress the

spring to the minimum working size according to the

specifications for this spring. The linear dimensions (height at

58