Page 40 - 4461

P. 40

5.Thermodynamics Gas Compressor

Introduction A gas compressor is a mechanical device that increases the pressure

of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

Compressors are similar to pumps: both increase the pressure on a fluid and both

can transport the fluid through a pipe. As gases are compressible, the compressor also

reduces the volume of a gas. Liquids are relatively incompressible; while some can be

compressed, the main action of a pump is to pressurize and transport liquids. The object

of all compressors is to raise the pressure of a gas with the minimum expenditure of

energy.

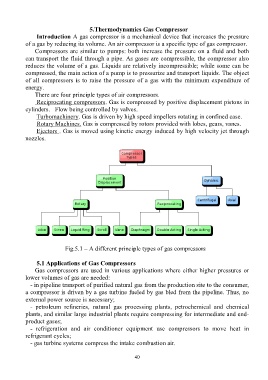

There are four principle types of air compressors.

Reciprocating compressors. Gas is compressed by positive displacement pistons in

cylinders. Flow being controlled by valves.

Turbomachinery. Gas is driven by high speed impellers rotating in confined case.

Rotary Machines. Gas is compressed by rotors provided with lobes, gears, vanes.

Ejectors . Gas is moved using kinetic energy induced by high velocity jet through

nozzles.

Fig.5.1 – A different principle types of gas compressors

5.1 Applications of Gas Compressors

Gas compressors are used in various applications where either higher pressures or

lower volumes of gas are needed:

- in pipeline transport of purified natural gas from the production site to the consumer,

a compressor is driven by a gas turbine fueled by gas bled from the pipeline. Thus, no

external power source is necessary;

- petroleum refineries, natural gas processing plants, petrochemical and chemical

plants, and similar large industrial plants require compressing for intermediate and end-

product gases;

- refrigeration and air conditioner equipment use compressors to move heat in

refrigerant cycles;

- gas turbine systems compress the intake combustion air.

40