Page 38 - 4461

P. 38

a b

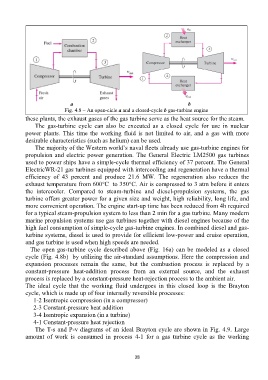

Fig. 4.8 – An open-cicle a and a closed-cycle b gas-turbine engine

these plants, the exhaust gases of the gas turbine serve as the heat source for the steam.

The gas-turbine cycle can also be executed as a closed cycle for use in nuclear

power plants. This time the working fluid is not limited to air, and a gas with more

desirable characteristics (such as helium) can be used.

The majority of the Western world’s naval fleets already use gas-turbine engines for

propulsion and electric power generation. The General Electric LM2500 gas turbines

used to power ships have a simple-cycle thermal efficiency of 37 percent. The General

ElectricWR-21 gas turbines equipped with intercooling and regeneration have a thermal

efficiency of 43 percent and produce 21.6 MW. The regeneration also reduces the

exhaust temperature from 600°C to 350°C. Air is compressed to 3 atm before it enters

the intercooler. Compared to steam-turbine and diesel-propulsion systems, the gas

turbine offers greater power for a given size and weight, high reliability, long life, and

more convenient operation. The engine start-up time has been reduced from 4h required

for a typical steam-propulsion system to less than 2 min for a gas turbine. Many modern

marine propulsion systems use gas turbines together with diesel engines because of the

high fuel consumption of simple-cycle gas-turbine engines. In combined diesel and gas-

turbine systems, diesel is used to provide for efficient low-power and cruise operation,

and gas turbine is used when high speeds are needed.

The open gas-turbine cycle described above (Fig. 16a) can be modeled as a closed

cycle (Fig. 4.8b) by utilizing the air-standard assumptions. Here the compression and

expansion processes remain the same, but the combustion process is replaced by a

constant-pressure heat-addition process from an external source, and the exhaust

process is replaced by a constant-pressure heat-rejection process to the ambient air.

The ideal cycle that the working fluid undergoes in this closed loop is the Brayton

cycle, which is made up of four internally reversible processes:

1-2 Isentropic compression (in a compressor)

2-3 Constant-pressure heat addition

3-4 Isentropic expansion (in a turbine)

4-1 Constant-pressure heat rejection

The T-s and P-v diagrams of an ideal Brayton cycle are shown in Fig. 4.9. Large

amount of work is consumed in process 4-1 for a gas turbine cycle as the working

38