Page 41 - 4461

P. 41

- sarious industrial, manufacturing, and building processes require compressed air to

power pneumatic tools;

- in the manufacturing and blow moulding of PET plastic bottles and containers;

- some types of jet engines—such as turbojets and turbofans - compress the air

required for fuel combustion;

- in hyperbaric oxygen therapy and other life support devices, compressors put

breathing gas into small volume containers, such as diving cylinders;

- submarines use compressors to store air for later use in displacing water from

buoyancy chambers to adjust depth;

- turbochargers and superchargers are compressors that increase internal combustion

engine performance by increasing the mass flow of air inside the cylinder, so the engine

can burn more fuel and hence produce more power;

- rail and heavy road transport vehicles use compressed air to operate rail vehicle or

road vehicle brakes—and various other systems (doors, windscreen wipers, engine,

gearbox control, etc.);

- service stations and auto repair shops use compressed air to fill pneumatic tires and

power pneumatic tools.

In the United States, there were 300 gas compressor manufacturers in 2011 producing

compressors for all of these uses. Although these factories were classified as small

business, the total 2011 sales for gas and air compressors was over $9 billion.

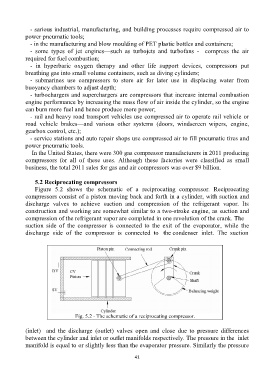

5.2 Reciprocating compressors

Figure 5.2 shows the schematic of a reciprocating compressor. Reciprocating

compressors consist of a piston moving back and forth in a cylinder, with suction and

discharge valves to achieve suction and compression of the refrigerant vapor. Its

construction and working are somewhat similar to a two-stroke engine, as suction and

compression of the refrigerant vapor are completed in one revolution of the crank. The

suction side of the compressor is connected to the exit of the evaporator, while the

discharge side of the compressor is connected to the condenser inlet. The suction

Fig. 5.2 - The schematic of a reciprocating compressor.

(inlet) and the discharge (outlet) valves open and close due to pressure differences

between the cylinder and inlet or outlet manifolds respectively. The pressure in the inlet

manifold is equal to or slightly less than the evaporator pressure. Similarly the pressure

41