Page 80 - 4274

P. 80

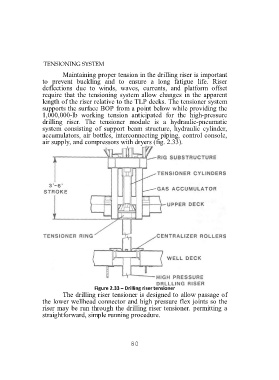

TENSIONING SYSTEM

Maintaining proper tension in the drilling riser is important

to prevent buckling and to ensure a long fatigue life. Riser

deflections due to winds, waves, currents, and platform offset

require that the tensioning system allow changes in the apparent

length of the riser relative to the TLP decks. The tensioner system

supports the surface BOP from a point below while providing the

1,000,000-lb working tension anticipated for the high-pressure

drilling riser. The tensioner module is a hydraulic-pneumatic

system consisting of support beam structure, hydraulic cylinder,

accumulators, air bottles, interconnecting piping, control console,

air supply, and compressors with dryers (fig. 2.33).

Figure 2.33 – Drilling riser tensioner

The drilling riser tensioner is designed to allow passage of

the lower wellhead connector and high pressure flex joints so the

riser may be run through the drilling riser tensioner. permitting a

straightforward, simple running procedure.

80