Page 7 - 4911

P. 7

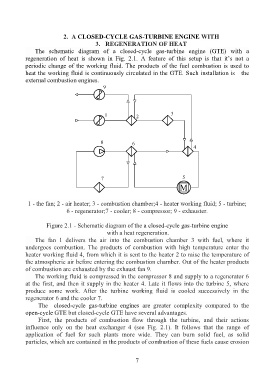

2. A CLOSED-CYCLE GAS-TURBINE ENGINE WITH

3. REGENERATION OF HEAT

The schematic diagram of a closed-cycle gas-turbine engine (GTE) with a

regeneration of heat is shown in Fig. 2.1. A feature of this setup is that it’s not a

periodic change of the working fluid. The products of the fuel combustion is used to

heat the working fluid is continuously circulated in the GTE. Such installation is the

external combustion engines.

9

1 2 3

8 6

4

7 5

M

1 - the fan; 2 - air heater; 3 - combustion chamber;4 - heater working fluid; 5 - turbine;

6 - regenerator;7 - cooler; 8 - compressor; 9 - exhauster.

Figure 2.1 - Schematic diagram of the a closed-cycle gas-turbine engine

with a heat regeneration.

The fan 1 delivers the air into the combustion chamber 3 with fuel, where it

undergoes combustion. The products of combustion with high temperature enter the

heater working fluid 4, from which it is sent to the heater 2 to raise the temperature of

the atmospheric air before entering the combustion chamber. Out of the heater products

of combustion are exhausted by the exhaust fan 9.

The working fluid is compressed in the compressor 8 and supply to a regenerator 6

at the first, and then it supply in the heater 4. Late it flows into the turbine 5, where

produce some work. After the turbine working fluid is cooled successively in the

regenerator 6 and the cooler 7.

The closed-cycle gas-turbine engines are greater complexity compared to the

open-cycle GTE but closed-cycle GTE have several advantages.

First, the products of combustion flow through the turbine, and their actions

influence only on the heat exchanger 4 (see Fig. 2.1). It follows that the range of

application of fuel for such plants more wide. They can burn solid fuel, as solid

particles, which are contained in the products of combustion of these fuels cause erosion

7