Page 90 - 4822

P. 90

Finally the water is collected in the water de-gassing

drum. Dispersed gas will slowly rise to the surface and pull

remaining oil droplets to the surface by flotation. The surface oil

film is drained, and the produced water can be discharged to sea.

Recovered oil in the water treatment system is typically recycled

to the third stage separator.

Gas treatment and Compression

The gas train consist of several stages, each taking gas from

a suitable pressure level in the production separator’s gas outlet,

and from the previous stage.

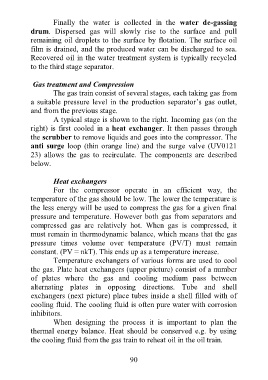

A typical stage is shown to the right. Incoming gas (on the

right) is first cooled in a heat exchanger. It then passes through

the scrubber to remove liquids and goes into the compressor. The

anti surge loop (thin orange line) and the surge valve (UV0121

23) allows the gas to recirculate. The components are described

below.

Heat exchangers

For the compressor operate in an efficient way, the

temperature of the gas should be low. The lower the temperature is

the less energy will be used to compress the gas for a given final

pressure and temperature. However both gas from separators and

compressed gas are relatively hot. When gas is compressed, it

must remain in thermodynamic balance, which means that the gas

pressure times volume over temperature (PV/T) must remain

constant. (PV = nkT). This ends up as a temperature increase.

Temperature exchangers of various forms are used to cool

the gas. Plate heat exchangers (upper picture) consist of a number

of plates where the gas and cooling medium pass between

alternating plates in opposing directions. Tube and shell

exchangers (next picture) place tubes inside a shell filled with of

cooling fluid. The cooling fluid is often pure water with corrosion

inhibitors.

When designing the process it is important to plan the

thermal energy balance. Heat should be conserved e.g. by using

the cooling fluid from the gas train to reheat oil in the oil train.

90