Page 76 - 4637

P. 76

In a cross section of 2-cone bit, cutters, or cones, are

mounted on bearing pins which are an integral part of the bit body.

This provides necessary strength to withstand loads imposed on

bits in present-day drilling. Radial loads are taken by the roller

bearing near the cutter base and by plain bearing near the nose.

The ball bearing retains the cutter on bearing pin and absorbs

all inward thrust loads. The primary capacity for outward thrust is

obtained by providing a plain thrust bearing at the ball race inner

flange face and at the inner end of the bearing pin.

This 5-element bearing design is typical for most types of

3-cone bits in sizes from 4 ¾ in. to 12 ¾ in. A recent trend in

bearing design is to replace roller bearings with a plain or journal

bearing as primary radial load element. In larger bits additional

space available permits use of two or more roller bearings for

increased capacity. Because of space limitations in most types of

bits smaller than 43 ¾ in., a ball bearing in combination with an

outer and inner plain bearing is used.

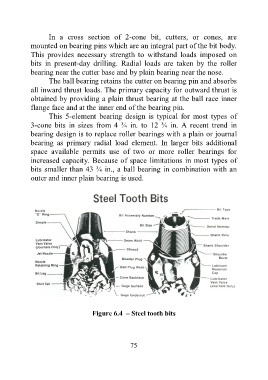

Figure 6.4 – Steel tooth bits

75