Page 346 - 4637

P. 346

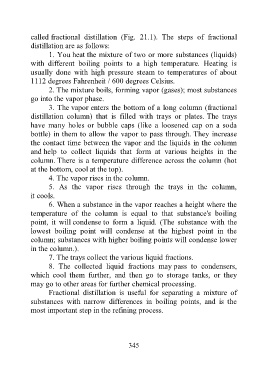

called fractional distillation (Fig. 21.1). The steps of fractional

distillation are as follows:

1. You heat the mixture of two or more substances (liquids)

with different boiling points to a high temperature. Heating is

usually done with high pressure steam to temperatures of about

1112 degrees Fahrenheit / 600 degrees Celsius.

2. The mixture boils, forming vapor (gases); most substances

go into the vapor phase.

3. The vapor enters the bottom of a long column (fractional

distillation column) that is filled with trays or plates. The trays

have many holes or bubble caps (like a loosened cap on a soda

bottle) in them to allow the vapor to pass through. They increase

the contact time between the vapor and the liquids in the column

and help to collect liquids that form at various heights in the

column. There is a temperature difference across the column (hot

at the bottom, cool at the top).

4. The vapor rises in the column.

5. As the vapor rises through the trays in the column,

it cools.

6. When a substance in the vapor reaches a height where the

temperature of the column is equal to that substance's boiling

point, it will condense to form a liquid. (The substance with the

lowest boiling point will condense at the highest point in the

column; substances with higher boiling points will condense lower

in the column.).

7. The trays collect the various liquid fractions.

8. The collected liquid fractions may pass to condensers,

which cool them further, and then go to storage tanks, or they

may go to other areas for further chemical processing.

Fractional distillation is useful for separating a mixture of

substances with narrow differences in boiling points, and is the

most important step in the refining process.

345