Page 31 - 4461

P. 31

cycle operating between the same temperature limits. However, it is still considerably

higher than the thermal efficiency of an actual cycle because of the idealizations

utilized.

The idealizations and simplifications commonly employed in the analysis of power

cycles can be summarized as follows:

1. The cycle does not involve any friction. Therefore, the working fluid does not

experience any pressure drop as it flows in pipes or devices such as heat exchangers.

2. All expansion and compression processes take place in a quasiequilibrium manner.

3. The pipes connecting the various components of a system are well insulated, and heat

transfer through them is negligible.

4.1 An Overview of Reciprocating Engines

Despite its simplicity, the reciprocating engine (basically a piston–cylinder device)

is one of the rare inventions that has proved to be very versatile and to have a wide

range of applications. It is the powerhouse of the vast majority of automobiles, trucks,

light aircraft, ships, and electric power generators, as well as many other devices.

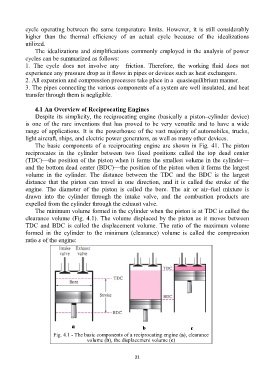

The basic components of a reciprocating engine are shown in Fig. 41. The piston

reciprocates in the cylinder between two fixed positions called the top dead center

(TDC)—the position of the piston when it forms the smallest volume in the cylinder—

and the bottom dead center (BDC)—the position of the piston when it forms the largest

volume in the cylinder. The distance between the TDC and the BDC is the largest

distance that the piston can travel in one direction, and it is called the stroke of the

engine. The diameter of the piston is called the bore. The air or air–fuel mixture is

drawn into the cylinder through the intake valve, and the combustion products are

expelled from the cylinder through the exhaust valve.

The minimum volume formed in the cylinder when the piston is at TDC is called the

clearance volume (Fig. 4.1). The volume displaced by the piston as it moves between

TDC and BDC is called the displacement volume. The ratio of the maximum volume

formed in the cylinder to the minimum (clearance) volume is called the compression

ratio ε of the engine:

Fig. 4.1 - The basic components of a reciprocating engine (a), clearance

volume (b), the displacement volume (c)

31