Page 136 - 6634

P. 136

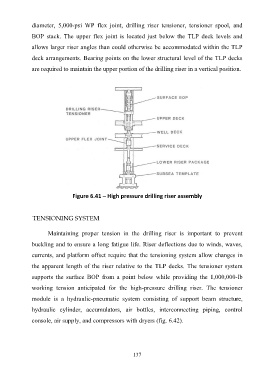

diameter, 5,000-psi WP flex joint, drilling riser tensioner, tensioner spool, and

BOP stack. The upper flex joint is located just below the TLP deck levels and

allows larger riser angles than could otherwise be accommodated within the TLP

deck arrangements. Bearing points on the lower structural level of the TLP decks

are required to maintain the upper portion of the drilling riser in a vertical position.

Figure 6.41 – High pressure drilling riser assembly

TENSIONING SYSTEM

Maintaining proper tension in the drilling riser is important to prevent

buckling and to ensure a long fatigue life. Riser deflections due to winds, waves,

currents, and platform offset require that the tensioning system allow changes in

the apparent length of the riser relative to the TLP decks. The tensioner system

supports the surface BOP from a point below while providing the 1,000,000-lb

working tension anticipated for the high-pressure drilling riser. The tensioner

module is a hydraulic-pneumatic system consisting of support beam structure,

hydraulic cylinder, accumulators, air bottles, interconnecting piping, control

console, air supply, and compressors with dryers (fig. 6.42).

137