Page 135 - 6634

P. 135

extension of the BOP, designed to withstand the maximum pressure and stresses

anticipated during drilling of the well under all weather conditions (Fig. 6.41). The

drilling-riser assembly consists of the lower riser package, the intermediate drilling

riser joints, and the top section.

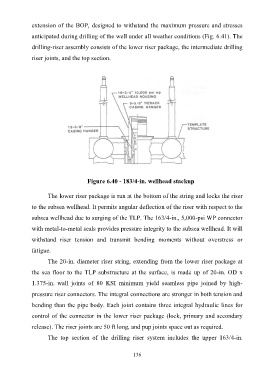

Figure 6.40 - 183/4-in. wellhead stackup

The lower riser package is run at the bottom of the string and locks the riser

to the subsea wellhead. It permits angular deflection of the riser with respect to the

subsea wellhead due to surging of the TLP. The 163/4-in., 5,000-psi WP connector

with metal-to-metal seals provides pressure integrity to the subsea wellhead. It will

withstand riser tension and transmit bending moments without overstress or

fatigue.

The 20-in. diameter riser string, extending from the lower riser package at

the sea floor to the TLP substructure at the surface, is made up of 20-in. OD x

1.375-in. wall joints of 80 KSI minimum yield seamless pipe joined by high-

pressure riser connectors. The integral connections are stronger in both tension and

bending than the pipe body. Each joint contains three integral hydraulic lines for

control of the connector in the lower riser package (lock, primary and secondary

release). The riser joints are 50 ft long, and pup joints space out as required.

The top section of the drilling riser system includes the upper 163/4-in.

136