Page 128 - 6634

P. 128

The US does not have a facility large enough to construct Classic SPAR

hulls. Therefore, almost all SPAR hulls have been manufactured overseas ,

typically in Finland, and then transported to the US, which increases the cost of the

project.

The hull of a truss SPAR is smaller, reducing both material cost and the cost

of transportation. Also for some truss SPARs, the actual truss system can be made

in the US and then mated with the hard tank when it arrives.

Because of the reduced size of the cylinders, fabrication of cell SPARs can

take place in the US, meaning that there is no transportation cost.

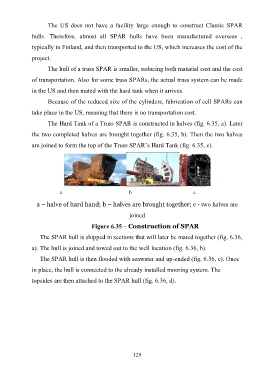

The Hard Tank of a Truss SPAR is constructed in halves (fig. 6.35, a). Later

the two completed halves are brought together (fig. 6.35, b). Then the two halves

are joined to form the top of the Truss SPAR’s Hard Tank (fig. 6.35, c).

a b c

a – halve of hard hand; b – halves are brought together; c - two halves are

joined

Figure 6.35 – Construction of SPAR

The SPAR hull is shipped in sections that will later be mated together (fig. 6.36,

a). The hull is joined and towed out to the well location (fig. 6.36, b).

The SPAR hull is then flooded with seawater and up-ended (fig. 6.36, c). Once

in place, the hull is connected to the already installed mooring system. The

topsides are then attached to the SPAR hull (fig. 6.36, d).

129