Page 323 - 4637

P. 323

Oil well pumps may be classed as either tubing or rod

pumps. In the case of tubing pumps, the barrel is run on the tubing

and the plunger is run on the rod string. In the case of rod pumps,

the complete unit is run on the rod string. Rod pumps have the

advantages of being more easily removed for servicing and less

susceptible to damage in running, but they offer less working area

for the plunger, since the maximum bore of a rod pump is

necessarily less than the maximum bore of a tubing pump for the

same size tubing.

Pumps may be further classed by the nature of the barrel.

Liner barrels are made up of jackets with sectional or one-piece

liners held in position by collars. Full barrels are one-piece tubes

threaded at each end.

Tubing pumps may be equipped at the lower end with

regular shoes or with extension shoes and nipples. The latter

arrangement permits a longer plunger stroke for a given length

pump barrel. In the nonextension style, however, there is less

space around the standing valve for accumulation of sand deposits.

Rod pumps are of either stationary barrel type with top or bottom

hold-down, or traveling barrel type. Stationary barrel pumps have

reciprocating plungers actuated by valve rods. In traveling barrel

pumps the barrel reciprocates over the plunger assembly.

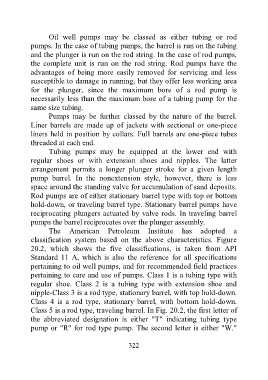

The American Petroleum Institute has adopted a

classification system based on the above characteristics. Figure

20.2, which shows the five classifications, is taken from API

Standard 11 A, which is also the reference for all specifications

pertaining to oil well pumps, and for recommended field practices

pertaining to care and use of pumps. Class 1 is a tubing type with

regular shoe. Class 2 is a tubing type with extension shoe and

nipple-Class 3 is a rod type, stationary barrel, with top hold-down.

Class 4 is a rod type, stationary barrel, with bottom hold-down.

Class 5 is a rod type, traveling barrel. In Fig. 20.2, the first letter of

the abbreviated designation is either "T" indicating tubing type

pump or "R" for rod type pump. The second letter is either "W."

322