Page 325 - 4637

P. 325

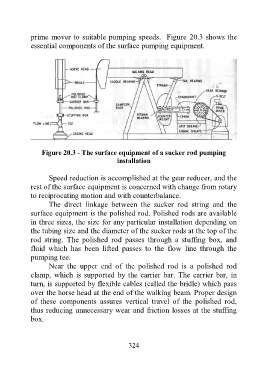

prime mover to suitable pumping speeds. Figure 20.3 shows the

essential components of the surface pumping equipment.

Figure 20.3 - The surface equipment of a sucker rod pumping

installation

Speed reduction is accomplished at the gear reducer, and the

rest of the surface equipment is concerned with change from rotary

to reciprocating motion and with counterbalance.

The direct linkage between the sucker rod string and the

surface equipment is the polished rod. Polished rods are available

in three sizes, the size for any particular installation depending on

the tubing size and the diameter of the sucker rods at the top of the

rod string. The polished rod passes through a stuffing box, and

fluid which has been lifted passes to the flow line through the

pumping tee.

Near the upper end of the polished rod is a polished rod

clamp, which is supported by the carrier bar. The carrier bar, in

turn, is supported by flexible cables (called the bridle) which pass

over the horse head at the end of the walking beam. Proper design

of these components assures vertical travel of the polished rod,

thus reducing unnecessary wear and friction losses at the stuffing

box.

324