Page 54 - 4822

P. 54

depend on the subsurface characteristics of the well, including the

diameter of the well (which is dependent on the size of the drill bit

used) and the pressures and temperatures experienced throughout

the well. In most wells, the diameter of the well hole decreases the

deeper it is drilled, leading to a type of conical shape that must be

taken into account when installing casing. The casing is normally

cemented in place.

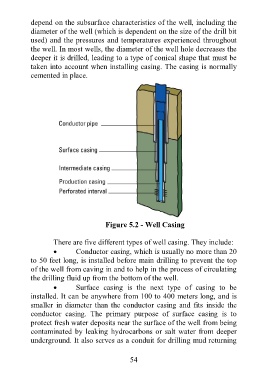

Figure 5.2 - Well Casing

There are five different types of well casing. They include:

Conductor casing, which is usually no more than 20

to 50 feet long, is installed before main drilling to prevent the top

of the well from caving in and to help in the process of circulating

the drilling fluid up from the bottom of the well.

Surface casing is the next type of casing to be

installed. It can be anywhere from 100 to 400 meters long, and is

smaller in diameter than the conductor casing and fits inside the

conductor casing. The primary purpose of surface casing is to

protect fresh water deposits near the surface of the well from being

contaminated by leaking hydrocarbons or salt water from deeper

underground. It also serves as a conduit for drilling mud returning

54