Page 28 - 4925

P. 28

down on the bit so the bit cutters can bite into the formation and drill it. Most of the

drill string is made up of drill pipe but crew members make up enough drill collars to

put the required weight on the bit.

Drill collars are either 30 or 31 feet (9.1 or 9.4 metres) long and those made to

API specifications range in diameter from 27/s to 12 inches (73.03 to 304.8

millimetres). To give you an idea of a drill collar’s weight, one that is 30 feet (9.1

metres) long and 6 inches (152.4 millimetres) in diameter weighs about 3,000

pounds (1,361 kilograms). Thus, if the drill crew made up ten joints of this particular

drill collar, the assembly would weigh 30,000 pounds (13, 610 kilograms). The

amount of weight a bit requires to drill efficiently varies considerably and depends

on the type of bit and the type of formation it is drilling. Nevertheless, 30,000

pounds is a good example of bit weight required.

A length of drill pipe is about 30 feet (9.1 metres) long, and drilling people call

each length a “joint of pipe”.

Each end of each joint is threaded. One end has inside or female threads; the

other has outside or male threads. The female end is called the “box,” and the male

end is called the “pin.” When crew members make up drill pipe, they insert, or stab,

the pin end in the box and tighten the connection. Crew members call the threaded

ends of drill pipe “tool joints.” Normally, the manufacturer welds the tool joints onto

the ends of the drill pipe and cuts the threads to API specifications.

Manufacturers do not add tool joints to drill collars. The walls of drill collars

are so thick that it is not necessary. Instead, the manufacturer cuts the threads directly

onto and in the drill collars. Like drill pipe, drill collars also have a box and pin end.

Thus, you can easily distinguish drill pipe from drill collars because drill

collars do not have the bulge at either end that characterizes the tool joints of drill

pipe.

Bits

A rig’s primary job is to rotate a bit on the bottom of the hole. The bit is the

business end of a drilling rig, because the bit drills, or makes, the hole. Bit

manufacturers offer several types of bit in many sizes. They design them to drill a

particular size of hole in a particular kind of formation.

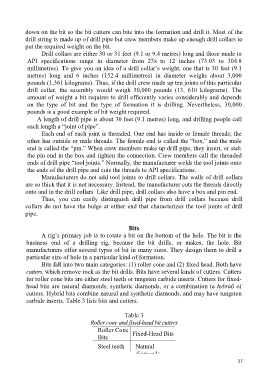

Bits fall into two main categories: (1) roller cone and (2) fixed head. Both have

cutters, which remove rock as the bit drills. Bits have several kinds of cutters. Cutters

for roller cone bits are either steel teeth or tungsten carbide inserts. Cutters for fixed-

head bits are natural diamonds, synthetic diamonds, or a combination (a hybrid) of

cutters. Hybrid bits combine natural and synthetic diamonds, and may have tungsten

carbide inserts. Table 3 lists bits and cutters.

Table 3

Roller cone and fixed-head bit cutters

Roller Cone Fixed-Head Bits

Bits

Steel teeth Natural

diamonds

27